|

|

Plastic felt is a prefabricated plastic- elastic membrane, formed by reinforcing polymeric

bitumen with a layer of non-woven plastic fabric at the central core.

It is further finished

with a thin polyethylene film on the outer surfaces.

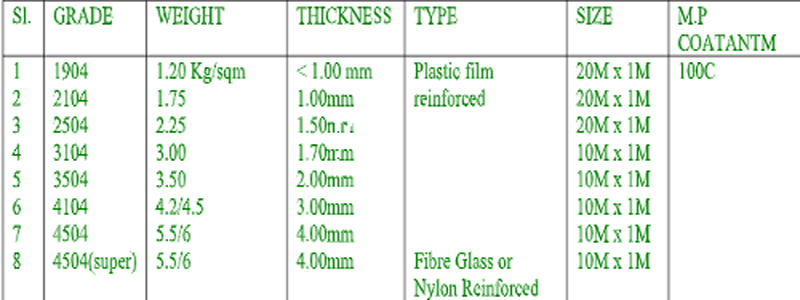

TECHNICAL DETAILS ABOUT PLASTIC FELT

1. Types of Plastic felt -

TECHNICAL DETAILS ABOUT POLYMERIC PLASTICFELT.

(TYPES OF PLASTIC FELT)

Physical and Chemical characteristics.

1. Heat resistance - Does not show any change in lamination applied vertically.

2. Elongation - The elongation capacity of plasticfelt is minimum 300%. It permits

the membrane to adapt to the structural movements caused by thermal jumps and

other reasons.

3. Resistance to Ageing - PLASTICFELT membrane has an extra-ordinary

resistance to ageing. Its properties vary very little more than 10 Years of service

life. The two most significant properties that show the ageing of an asphaltic

bitumen are the diminishing of penetration and pliability. Polymeric bitumen

differs from traditional asphaltic coatants in maintaining its high level of

penetration and pliability even after years.

4. Low Temperature Flexibility - The polymeric plasticfelt membrane maintains

its flexibility even upto-10C.

5. Chemical Resistance -

Good against dilute acid solutions.

Good against oxidising acids.

Good against sulphurous solutions.

Good against alkaline solutions.

Bad against solvents. |

|